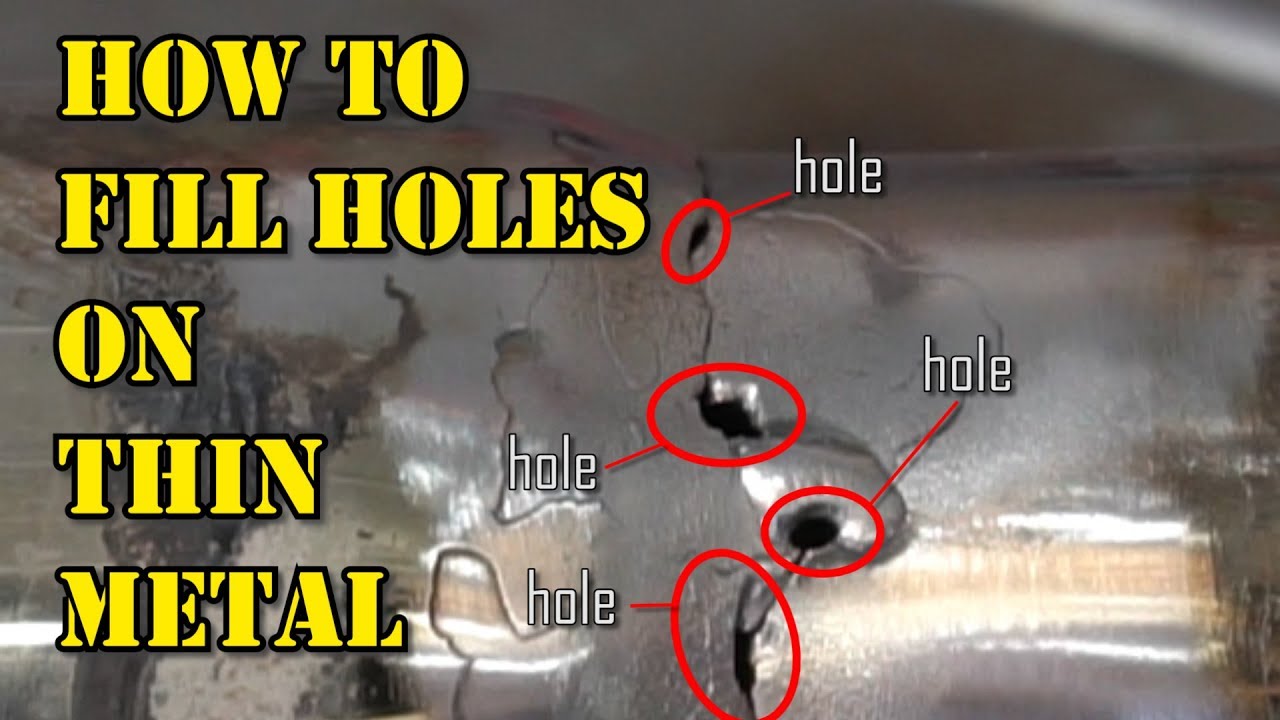

Rusty Thin Sheet Metal Blowing Holes Welding

My names matt urch and i own and.

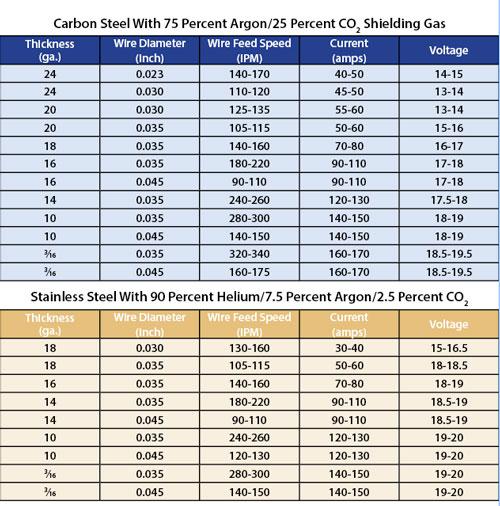

Rusty thin sheet metal blowing holes welding. Try going for a wire of 023 inches when welding sheet metal. The butt weld page showed how to do a seam weld using a continuous torch movement. I m welding very t. The kind of plug to use depends on how the thin metal is being used.

In order to weld sheet metal or patch panel you have to follow certain rules and use specific techniques. Stick welding sheet metal with 6013 rods. If the hole needs to contain a liquid a rubber washer can go on the sheet metal screw to render it water tight. Rusted body panels need to be repaired.

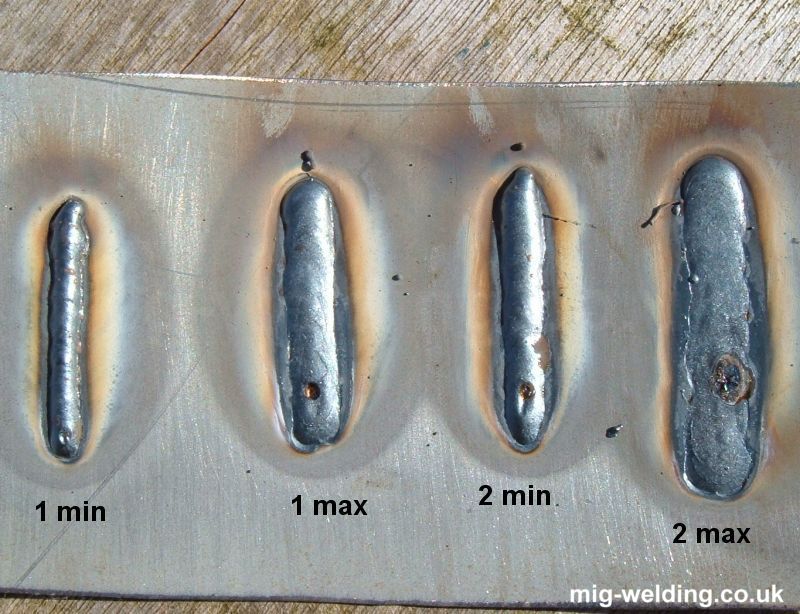

Proper technique will come with practice and experience. In this video im showing you the process i use to do small rust repairs where a complete panel. The photo is 1mm steel welded at a power setting normally reserved for 2mm steel. Try welding with a scrap sheet metal piece and practice many times until you start working on more important projects.

Here s a quick video on how to plug weld sheet metal using mig without blowing yourself a bigger hole than you started with. Also it will ensure that you don t get any warping of the materials you are working on and no burn through as well. This is the thinnest sheet metal i have ever welded using this process. Perhaps a simple rivet or sheet metal screw can be secured in the hole.

Make sure to use an electrode wire that is thinner as it uses lesser heat and prevents blowing holes on to the sheet metal. If you re repairing an old car then you ll almost certainly need to weld rusted sheet metal at some point. Try applying that technique to steel less than 1mm in thickness and you are likely to blow a hole in the metal. Sheet metal welding techniques.

Holes in thin metal can be filled with plugs.